Quality

The Swiss Army Knife of Manufacturing

June 22, 2020

Did you know that you can streamline your sourcing and assembly with suppliers such as Prismier? We not only manufacture the subcomponents, but we provide the value add of integrating both subassemblies and complete final assemblies. Read on to learn about the many advantages of this arrangement.

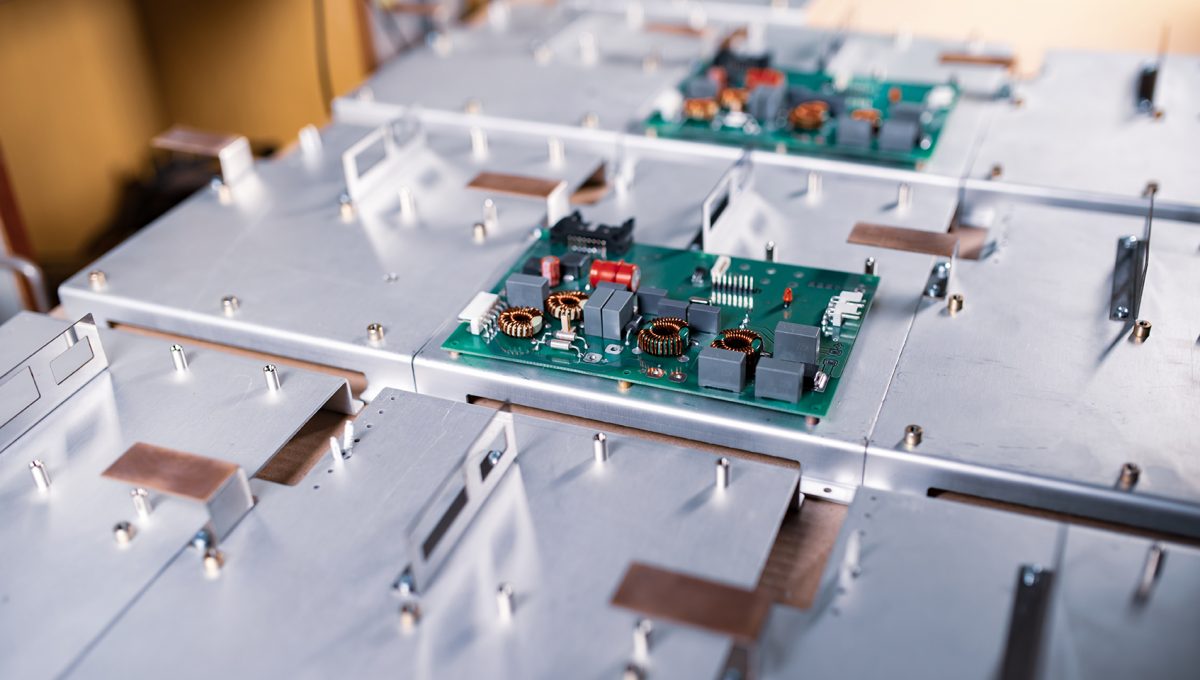

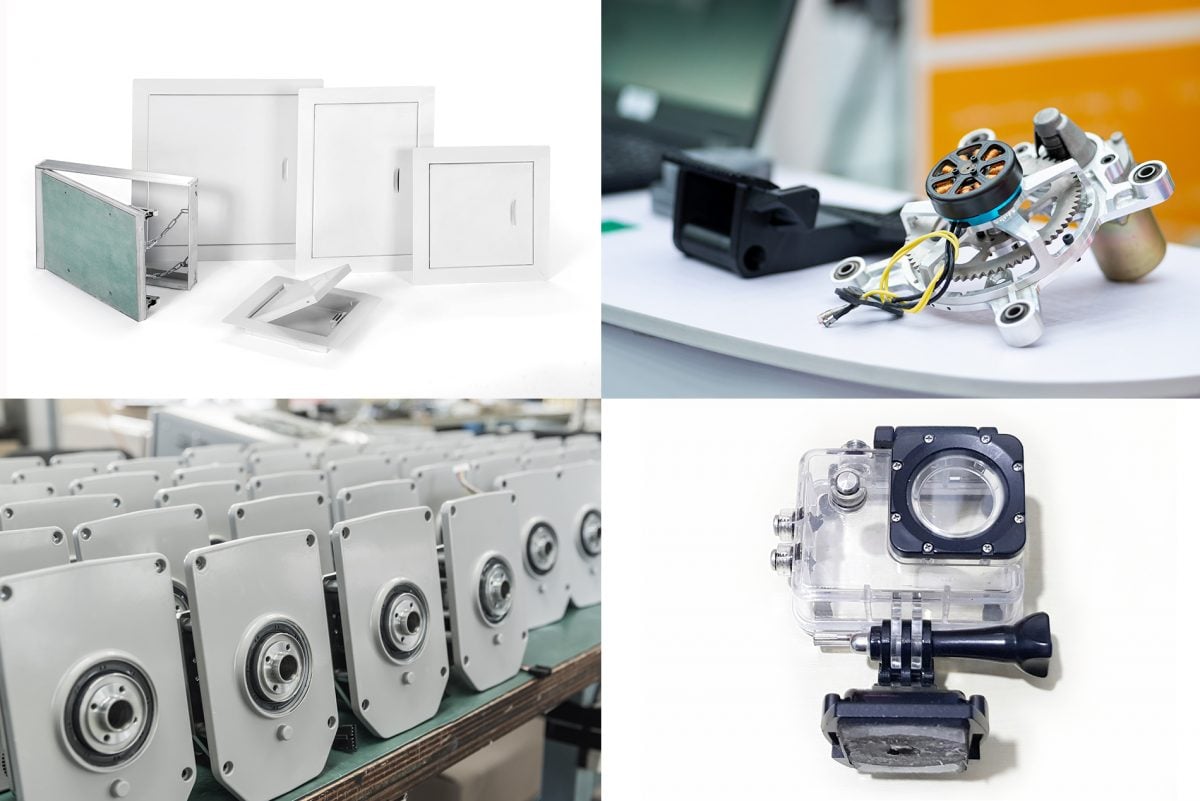

When completed, such products perform a variety of everyday functions. The power supply in a desktop computer is an excellent example, as is the computer itself, but countless other electromechanical assemblies exist. These range from the internal workings of the cash machine you stopped at on the way to work, the control panel on the tractor you drove all day, or the automatic garage door opener that lets you in each night.

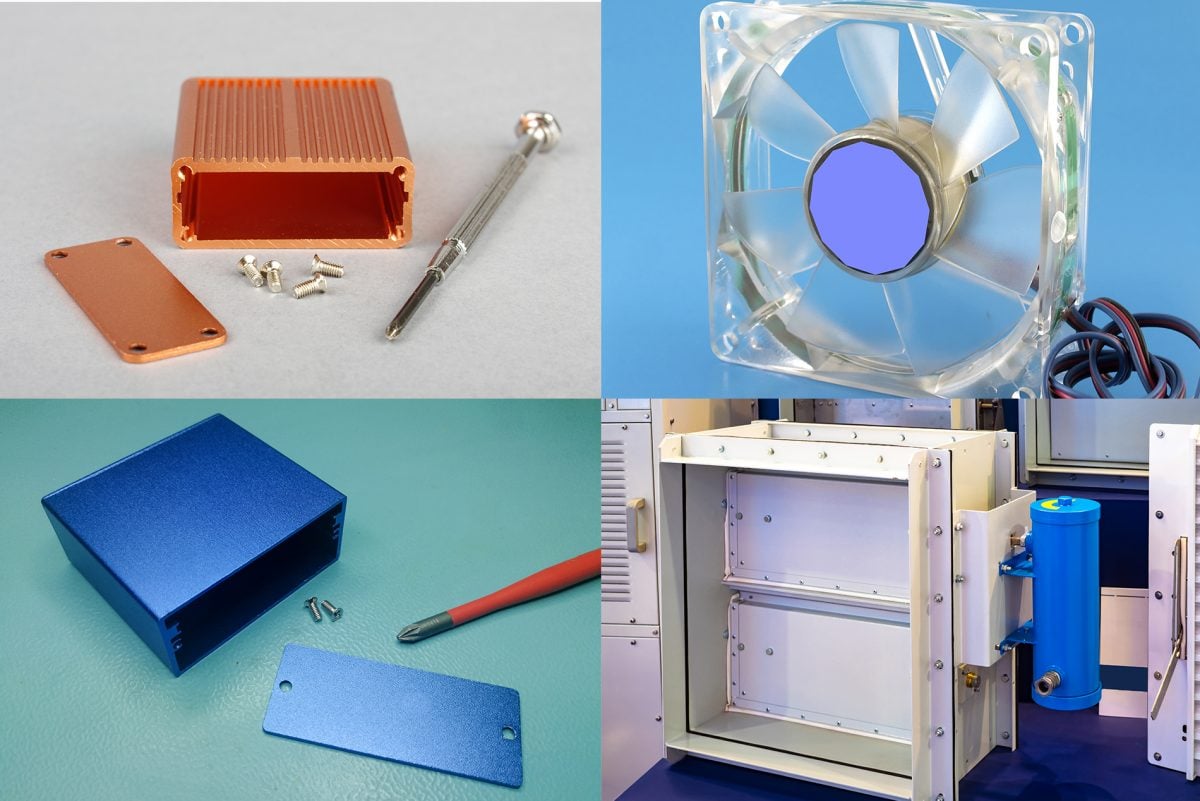

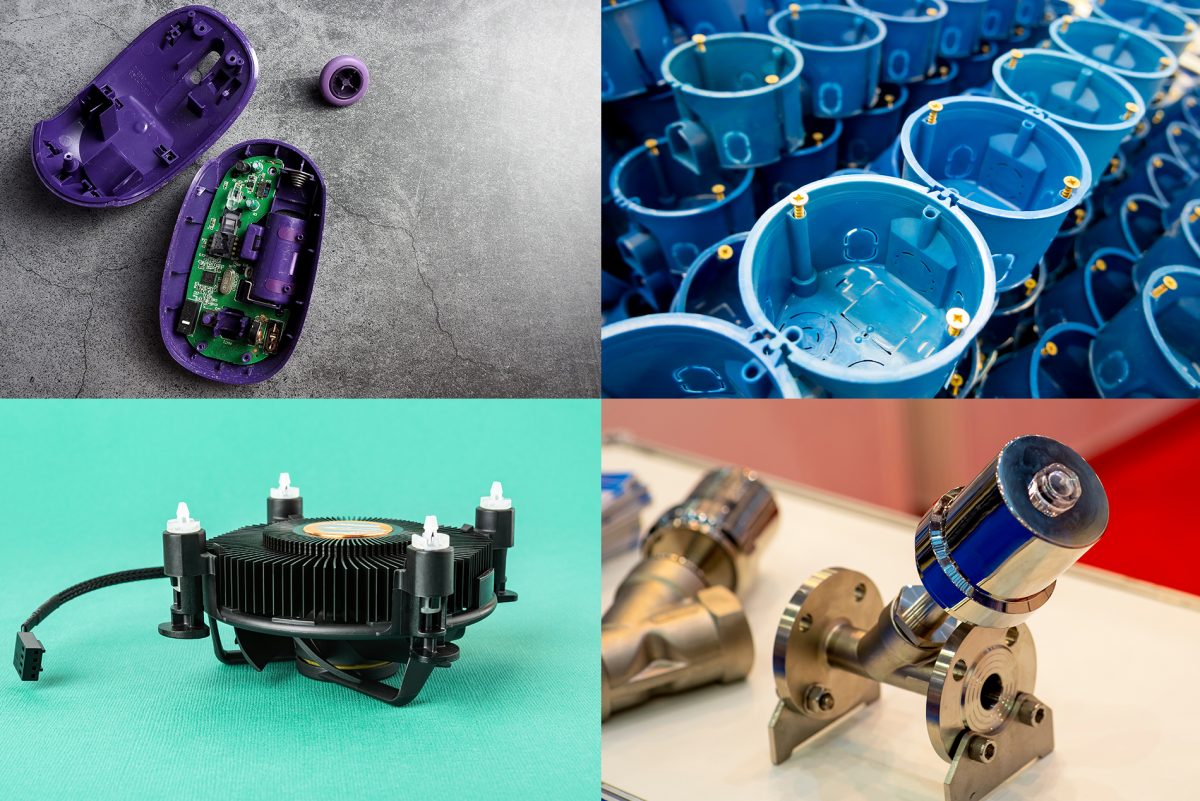

Most of these are known as box build assemblies, although other non-orthogonal assemblies are certainly possible. From the mechanical side, these are often referred to as enclosures, housings, chassis, or weldments. Regardless, these clever contraptions usually begin life in one of the following ways:

Any of these parts could then be sent to the powder coating or painting line for finishing. From there, the completed housing heads to the assembly department.

As mentioned, a variety of electronic and mechanical components might be attached here, hence the name “electromechanical assembly.” Fans and covers are often screwed into place. Bearings are pressed onto rotating shafts. LED lights and switches become connected to power supplies, while wheels, brackets, and locking mechanisms get installed and adjusted. It’s a long list, and again, not all electromechanical assemblies are boxy in nature, although these certainly represent a big chunk of it.

They should also be happy to apply any labels, stickers, or artwork that accompany the final assembly in addition to any other mechanical items to be assembled including latches, handles, locks, and gaskets. In many cases your mechanical supplier will also install the PCBs and wiring harnesses mentioned earlier, although they will likely prefer to work with your preferred suppliers.

Take that one step further. Suppliers like Prismier provide value added services such as VMI (vendor-managed inventory). kitting services, and enhanced packaging solutions to save you time and money. From kitting and bar coding to custom crating and boxing, the supplier can have everything ready to ship to your end consumer—right down to inserting an instruction manual. Single-sourcing of these kits and assembled products significantly shortens the supply chain. Eliminate extra steps between you and your customer by allowing the supplier to handle your complete packaging needs.

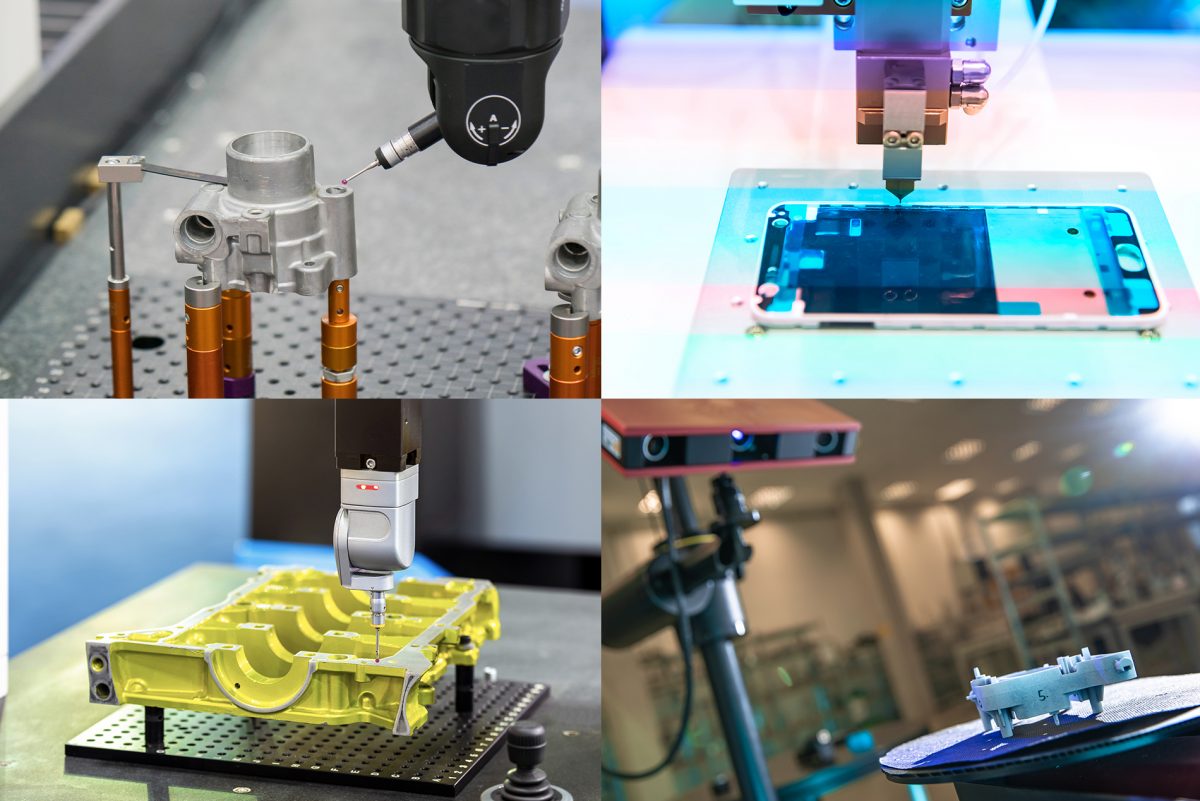

Aside from using CNC machinery and advanced software systems to design, manufacture, and assemble a huge variety of products, at Prismier we also practice Lean Manufacturing principles such as Kan-Ban, 5S, SMED, and continuous or “single-piece” flow, all key concepts of the Toyota Production System.

As its name implies, continuous flow manufacturing moves parts from one operation in small batches—often just one or two pieces—rather than completing all of Op. 10 on a job before moving on to Op 20. Work-in-process is thus greatly reduced, and if a defect is found (it happens to the best of us), only that batch of parts is affected. Best of all, customers can expect to receive their parts or assemblies much sooner than they otherwise would, at the best price possible. At Prismier we call it Manufacturing Simplified.

If you'd like to know more, pick up the phone and call us at (630) 592-4515 or email us at sales@prismier.com. Or if you're ready for a quote, email quotes@prismier.com. We'll be happy to discuss your options.