Quality

The Swiss Army Knife of Manufacturing

June 22, 2020

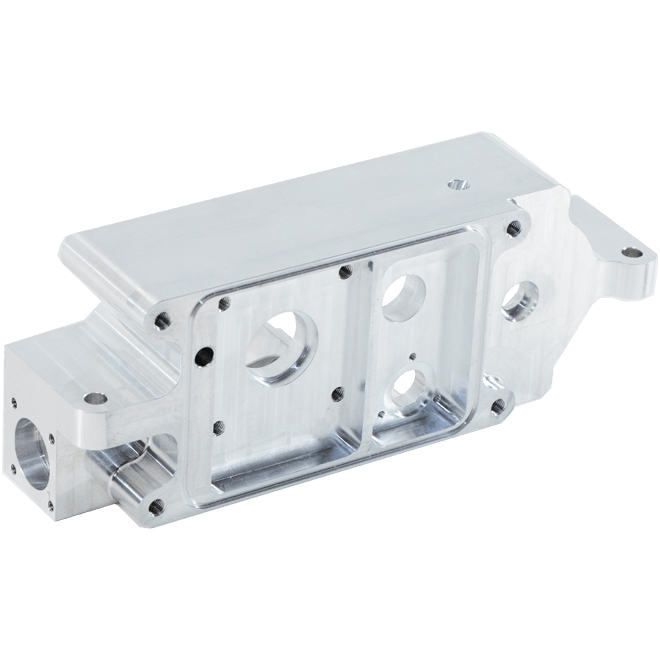

When speed-to-market counts, you don’t have time to wait on a prototype. You need a production-ready part now. At Prismier, we’re experts at making chips. Our dedicated prototype equipment includes 3-, 4-, and 5-axis machining and advanced turning capabilities to provide comprehensive solutions to an array of industries. Get in front of your customer faster with Prismier.

We get it. You need a production-ready prototype fast. That’s why we deliver parts in as little as 24 hours. From super-speed CNC machines with high tool-changer capacity, to high-speed spindles with 12,000 RPM, to dedicated equipment for prototyping, our entire process is designed to meet your deadlines. What it all boils down to: faster throughput and faster machining for faster turn-around on your project.

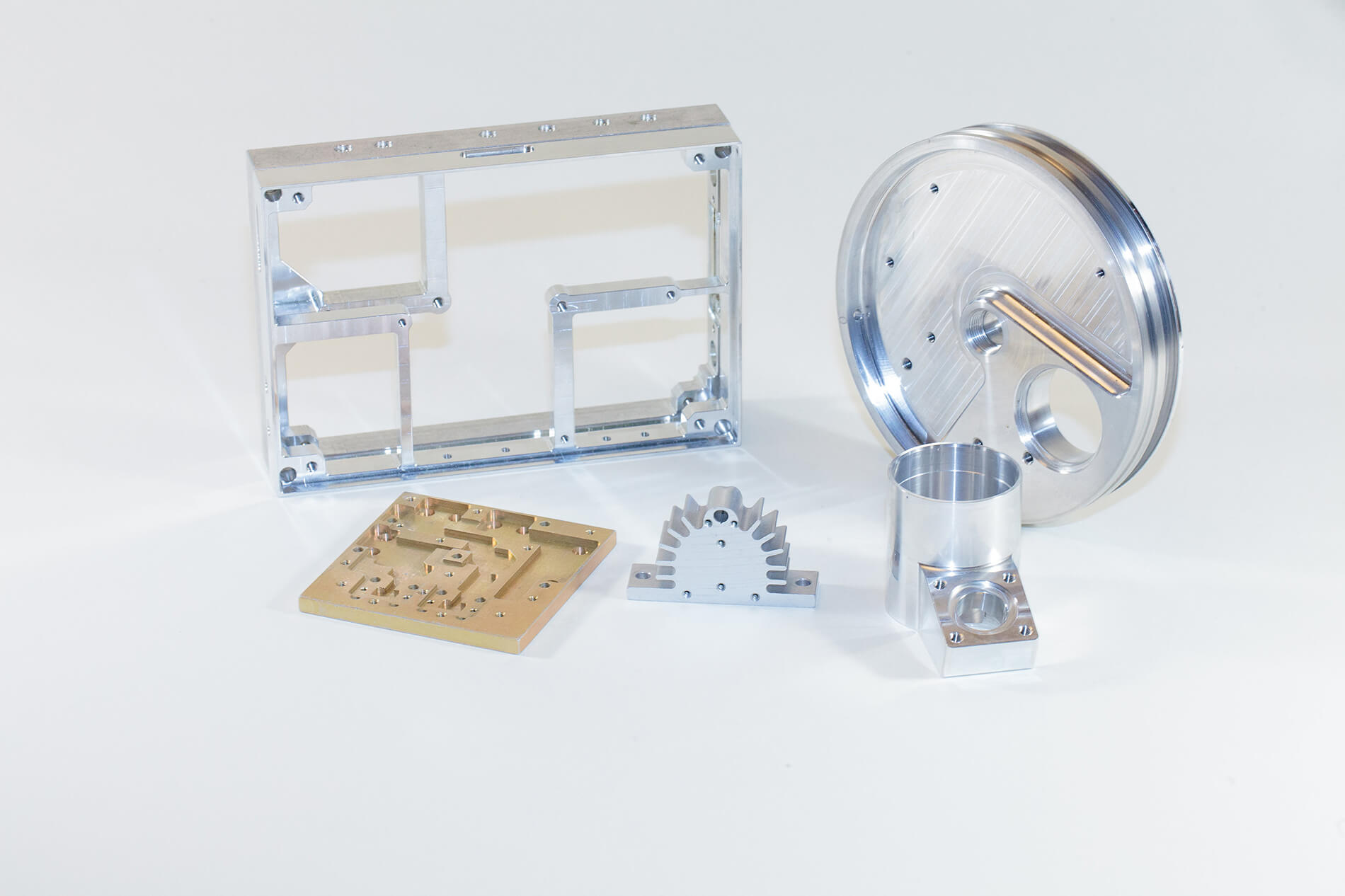

Think your part might be too complex? Not for us. We have the capability and know-how to transform designs of the most intricate geometry into sophisticated production-ready parts… pronto. From the smallest scale to large, our ability to machine and turn projects within a wide array of sizes, shapes, and metals means you don’t have to shop around for multiple manufacturers. With Prismier, you get comprehensive solutions to meet your needs, all under one roof.

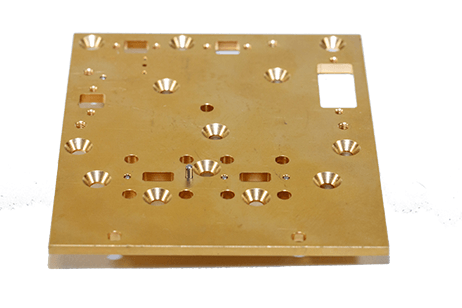

When the success of your design rides on the accuracy of your prototype, an “approximate” part isn’t close enough. At Prismier, we ensure fidelity to design by scrutinizing quality down to the most precise level. Between in-process quality checks and FaroArm technology, we deliver prototypes that match your design intent. You can confidently test your design knowing your part is as real-world as it gets.

Your design is sharp. The prototype looks good. But can it be mass produced? With Prismier, there are no surprises when it comes time for production. We combine our extensive advanced subtractive manufacturing expertise with our proven design for manufacturing process to ensure your prototype can be manufactured to scale as cost-effectively as possible. If there’s a way to cut costs, improve quality, or enhance the transition to production, we’ll find it.

Moving from prototype to production is seamless with Prismier. As a global manufacturer, we make manufacturing simplified with multiple cost-effective options aligned to your needs. Diversified solutions for custom metal and plastic parts means you work with a single source for everything from production through delivery. We have the technology, equipment, and expertise to provide diecast and production machining and turning services. From accepting files in the format of your preference to providing online bill pay, we are here to support you.

Our helpful and highly trained team of experts won’t waste your time with guesswork. Whether it’s Prototype Sheet Metal, Precision Sheet Metal Fabrication, Small to Micro Stamping, Production Metal Stamping, soft tooling or hard tooling, one part or one million, we serve any industry, and we know how to get you what you need.