Quality

The Swiss Army Knife of Manufacturing

June 22, 2020

It is Prismier’s goal to be a world-class organization, as defined by our customers, by providing a flexible and responsive customer experience.

We review all 3D Model and Drawing requirements to make sure we know exactly what critical dimensions and tolerances we need to measure and adhere to.

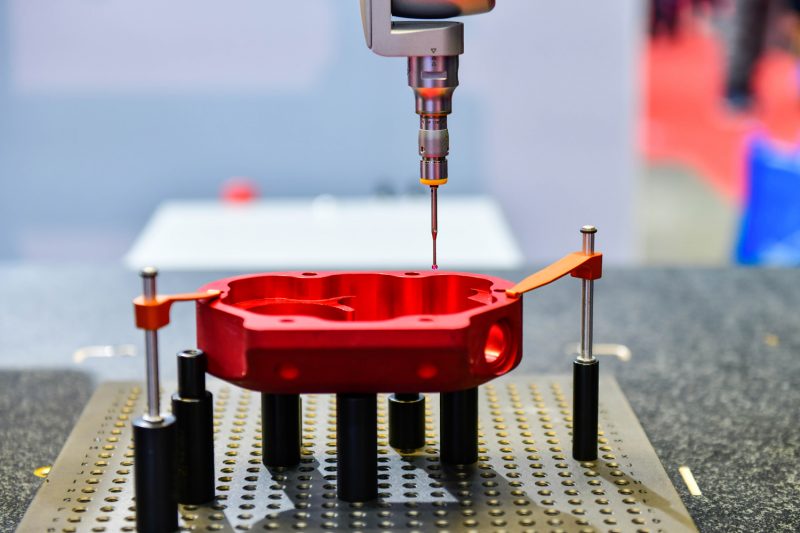

At every single transformation (or setup) an inspection specification is drafted.

We statistically monitor all manufacturing in process. Additionally we go above and beyond for cosmetic differences.

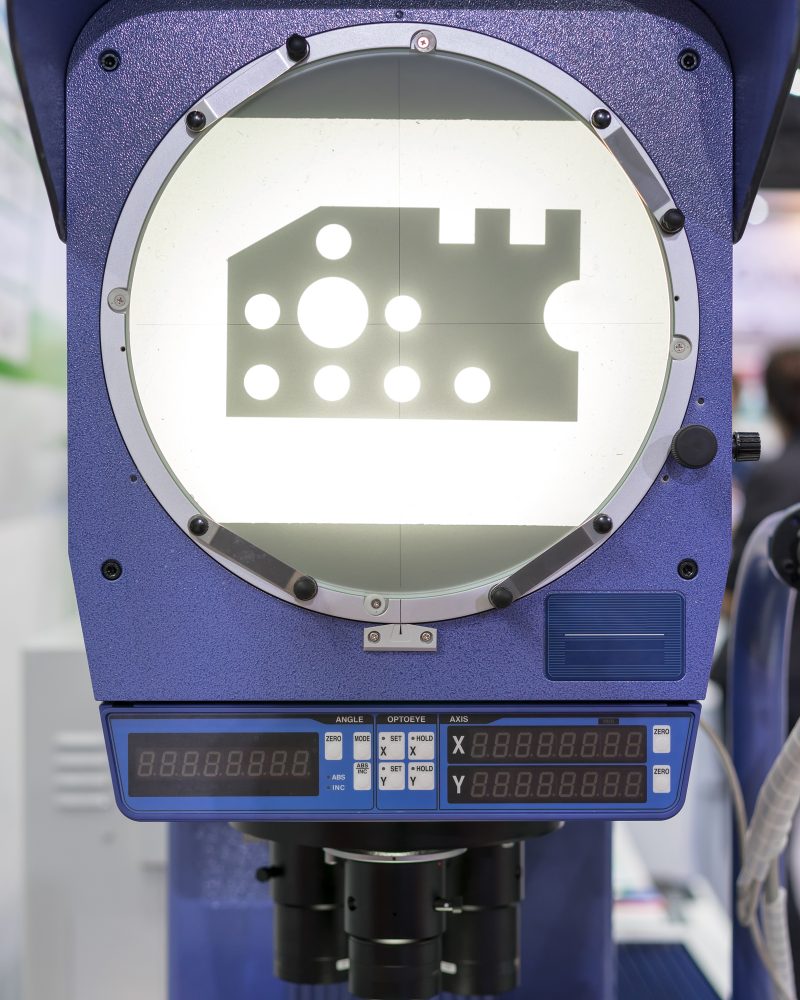

Our final inspection entails measuring and confirming all critical dimensions and tolerances.

Final packaging reviewed for safe transit and delivery.

Prismier’s Certified Gold Standard is built upon ISO 9001:2015 and Lean Six Sigma manufacturing practices to provide a quality system to assure that we meet exacting customer specifications. Our continuous internal training, rigorous documentation and record-keeping oftentimes negate the need for expensive certifications that aren’t required for every job.

It’s all in effort to make sure that every single part or assembly that leaves our facilities arrives exactly as you’d expect it to. Your parts are the correct finish, the correct size, with proper hardware inserted, and holes tapped to the proper thread count.

Of course when you request a quote from Prismier we offer other levels of quality inspection such as First Level Articles, PPAP Levels I and II, and AS9102 but at a bare minimum you’ll know your parts and the processes it required went through a meticulous and exacting quality inspection standard.

“Quality is never an accident. It is always the result of intelligent effort.”

Jason Sabala – Director of Quality

We get it, it’s all about the hustle here too. But without strict quality processes in place you’re just going to move fast and rush things out the door. Prismier embraces rigorous in-process quality checks which raise the bar for repeatable results no matter if you require 500 or 5,000 parts.

Prismier does Statistical Process Control (SPC) down to 1 piece. And on all parts we adhere to an Acceptance Quality Limit (AQL) 4.0 (w/C=0). All quality jargon aside: we yearn for your exacting standards and can’t wait to exceed your expectations.

Prismier also embraces the APQP Process and its 7 Major Elements:

Great people with a commitment to quality is where it starts for Prismier but good people need precision tooling and advanced technology.

At Prismier, we utilize a custom quality management software to manage your parts life-cycle of quality and Prismier’s continual improvement. In partnership with a leader in quality management solution software provider, we have combined our Enterprise software system with all aspects of our quality process. This dynamic relationship allows Prismier to:

There’s no need to compromise quality for production convenience. With Prismier, you can have it all. Keep your project in flight by contacting us today.