Quality

The Swiss Army Knife of Manufacturing

June 22, 2020

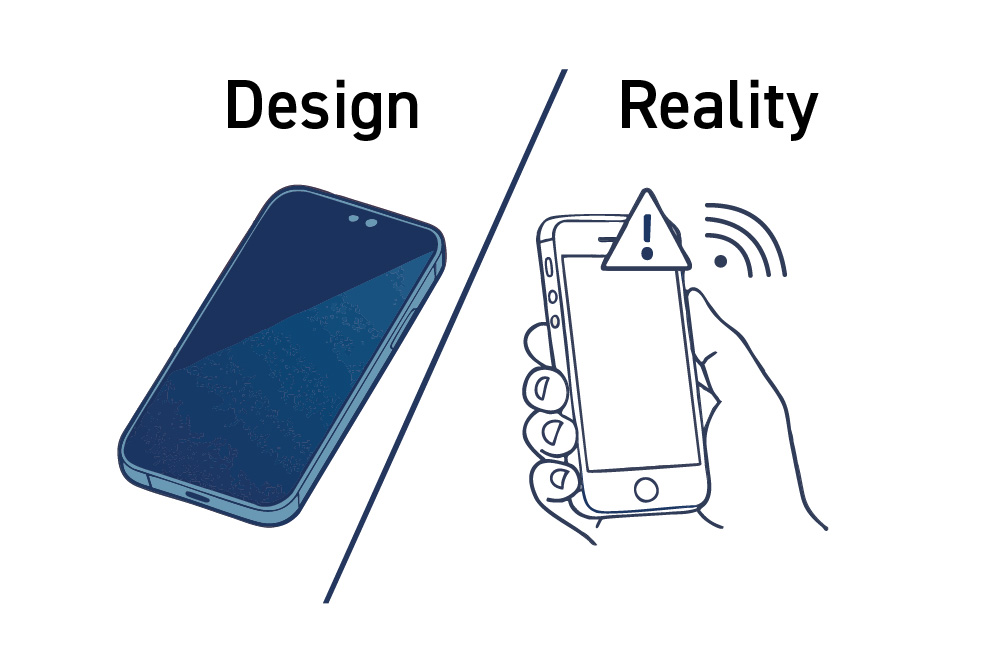

In the summer of 2010, Steve Jobs was supposed to be on vacation in Hawaii. Instead, he was fielding phone calls about dropped calls. Apple’s freshly launched iPhone 4, with its striking stainless-steel band that doubled as an antenna, had developed a very public problem: grip the phone in just the wrong way, and signal strength plummeted.

The press dubbed it “Antennagate.” Jobs, famously a perfectionist, had pushed for the seamless look of that metal frame. The product looked great, but it was also deeply flawed. You might say that particular version of the iPhone was the Pontiac Fiero or New Coke of smart phones.

Antennagate went on to become a cautionary tale for anyone who designs parts, and serves to highlight the gap between an elegant vision and the stubborn reality of how stuff is made on a manufacturing floor along with how it performs in the real world.

For example, in CAD everything can look perfect, including straight edges, sharp corners and impossibly thin walls. But machines don’t deal in ideals; they deal in physics, tooling, and tolerances. And so what looks good on a screen may not work (or may cost more than a new iPhone) once it hits production.

But in fairness to Jobs and the iPhone…Apple’s stumble didn’t define the product – it refined it. Within a year the antenna issues were resolved, sales skyrocketed, and the device went on to become one of the most successful products in history.

At Prismier we believe setbacks in design, like Antennagate, aren’t roadblocks – they’re springboards. By bringing manufacturability expertise into the process early, we help companies turn early missteps into smarter, stronger products that thrive in the market.

Few tools have ever given designers as much power as CNC machines. They are the ultimate tool for translating concepts into components, down to the smallest detail; giving designers an incredible sense of freedom.

But like Apple discovered with the iPhone antenna, freedom isn’t the same as wisdom, and wisdom is exactly what the machine can’t provide.

Why? Because while machines will do what they’re told, they won’t tell you if you’ve made life unnecessarily hard on yourself.

The culprit could be a sharp inside corner, a paper-thin wall, or a design that demands ten different tool changes. Put simply, the machine doesn’t care about cost or time… but you certainly do. And so without designing for manufacturability in mind, even the best-looking design can become a budget nightmare.

This is why Design for Manufacturability (DFM) is so important. It isn’t about limiting creativity – it’s about creatively working with the strengths and limitations of CNC machines. To that end, DFM can be distilled down to three simple questions: how will this design behave when it leaves the screen and meets the cutter? How will the design fit within your budget? And how will it behave in the wild?

If you can answer those three questions honestly and accurately, you’re already way ahead of the curve.

Ambitious designs often clash with manufacturing realities, as seen in ultra-thin, seamless electronics that look perfect (at least in theory) but which can be tricky to manufacture and assemble.

While CAD software allows incredible freedom to “make whatever you want,” the true test comes when turning that digital vision into a physical part. Ignoring the practical limitations of CNC machining during design often leads to unnecessary cost increases and production delays.

So with all that said, here are a few spots where smart DFM choices can save you headaches – and maybe even a Hawaiian vacation:

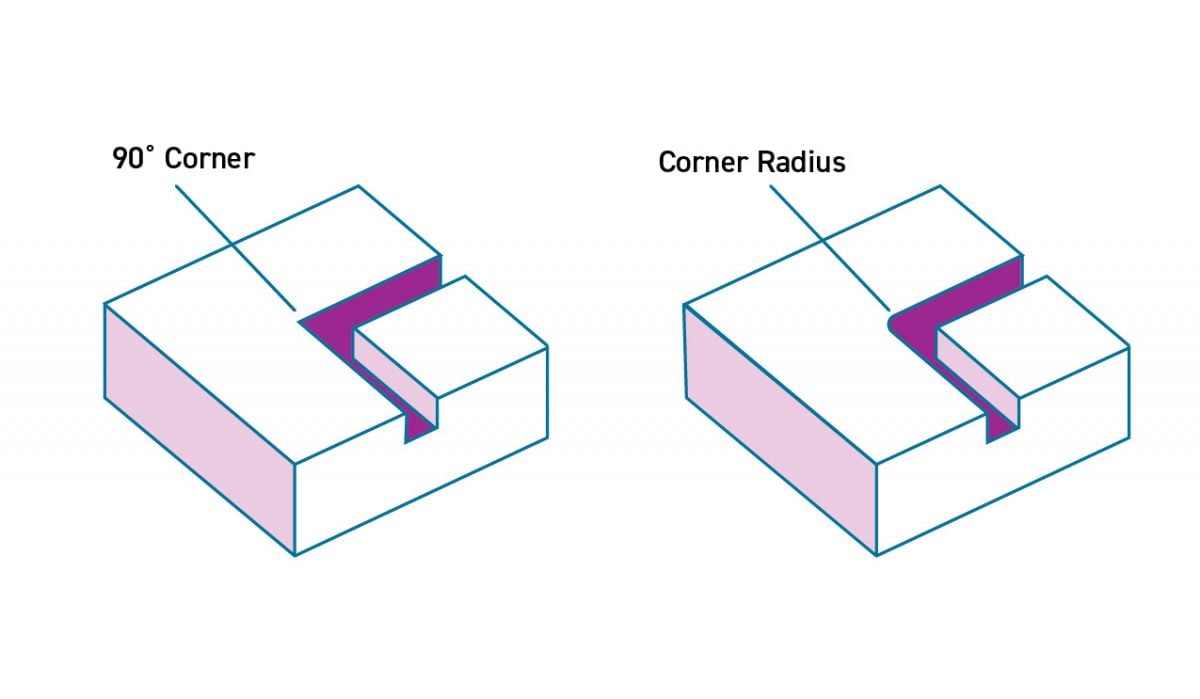

You can’t put a square peg in a round hole, and the same goes for sharp internal corners in CNC machining. On a CAD model, a perfectly sharp 90-degree corner looks clean and precise, but in reality they cause headaches.

Standard mills can’t make a perfectly sharp inside corner – they’re round, so they always leave a radius. Getting a true 90-degree inside edge often means multiple tool changes; starting with a standard cutter, swapping to a thinner profile, and sometimes chasing the last bit with a tiny specialty tool.

Alternatively, you can use EDM, which burns away metal with sparks, or broaching, which slices it with a shaped tool. All of these options work, but they typically add time, cost, and complexity, and so the real question is, do you really need that corner perfectly sharp? Because this labor-intensive process can add multiples to production costs for just that feature.

For many functional contexts, like an internal pocket holding a motor, a perfect square corner isn’t critical, and so a smart approach is to design with the tool in mind. Incorporating a small radius lets a single cutter clear material in one efficient pass, avoiding costly tool swaps and wasted machine time.

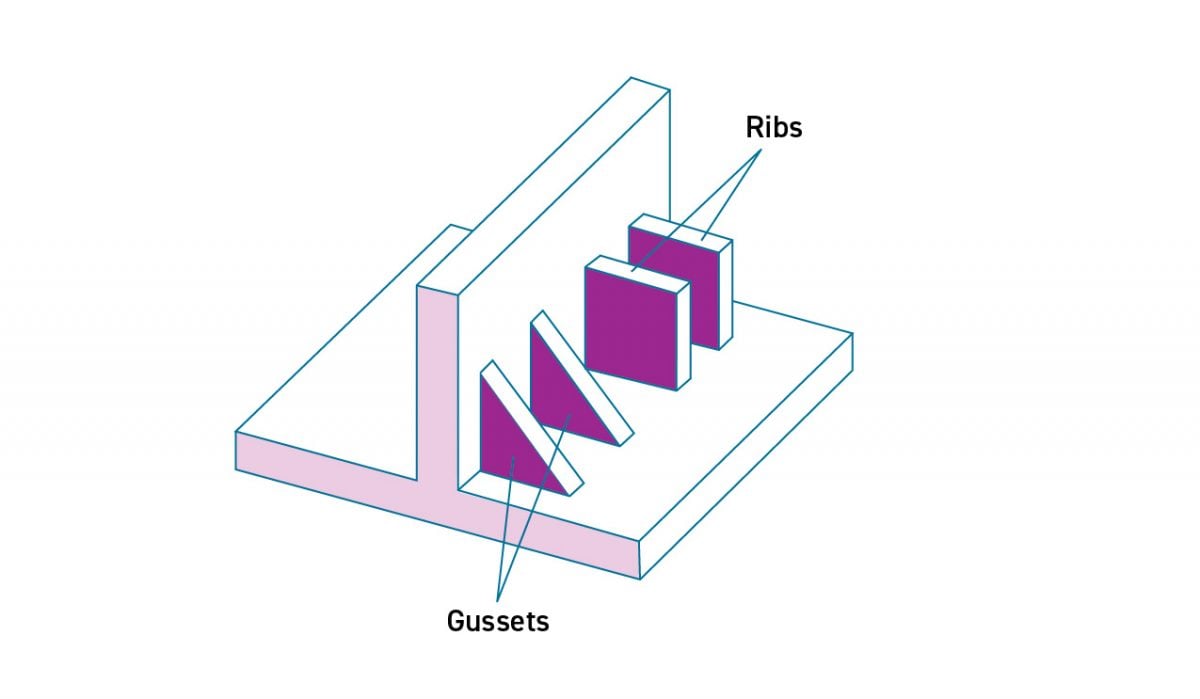

The push for thinner, sleeker walls often looks great in a digital model, but machining tells a different story. Walls that are too thin can flex, vibrate, or even break under cutting forces, turning what seemed like a minor design choice into scrapped parts and costly re-runs.

Accounting for material strength and stability during the design phase helps avoid these surprises, balancing aesthetic goals with manufacturability. Thoughtful wall thickness isn’t just safer – it keeps production predictable and efficient.

Beyond manufacturing, thin walls can degrade quickly under operational stresses, potentially leading to premature part failure. A more pragmatic approach adds strategic thickness where possible, or reinforces thin sections with gussets or ribs that balance design intent with durability.

This foresight transforms a potentially fragile part into one that is robust, survives the manufacturing process, and performs reliably in the field, addressing the tension between “less material” and practical part strength.

Most parts receive some form of post-processing like anodizing, plating and powder coating, or other finishes, with each process subtly changing part dimensions. Even a thin coating can alter fit or clearance: anodizing adds a few microns per surface, powder coating slightly more, and plating can build unevenly on edges and corners.

This means that a bore or slot that looks perfectly straight off the machine may measure differently once finished.

Experienced designers account for these effects early. They anticipate how coatings will change critical features, adjusting tolerances or clearances to ensure the part meets specifications in its final, as-used state.

When you need a pristine, uncoated mating surface alongside a finished surface on the rest of your part, masking is worthy of consideration. Rather than stripping away coating or reworking tolerances after the fact, Prismier can apply high-temperature tape, plugs, or custom-cut films to these critical areas before any finishing step; meaning those zones stay bare metal and exactly to spec, while everything else receives its anodize, powder coat, or plate treatment.

The real advantage of masking lies in simple upfront planning. Prismier can help you identify the holes, slots, and edges that must remain exact, then cover those areas with high-temperature tape, plugs, or films before the finishing process. This means that when the part comes out of the anodizing, powder coat, or plating process, we just peel away the masks and uncover perfect surfaces that are still right on spec.

By baking masking into the process map up front, it eliminates late-stage panic and costly back-and-forth. One careful setup (with both CAD and masking planned together) and one finish run followed by peeling away the masks gives you surfaces that meet spec on the first pass.

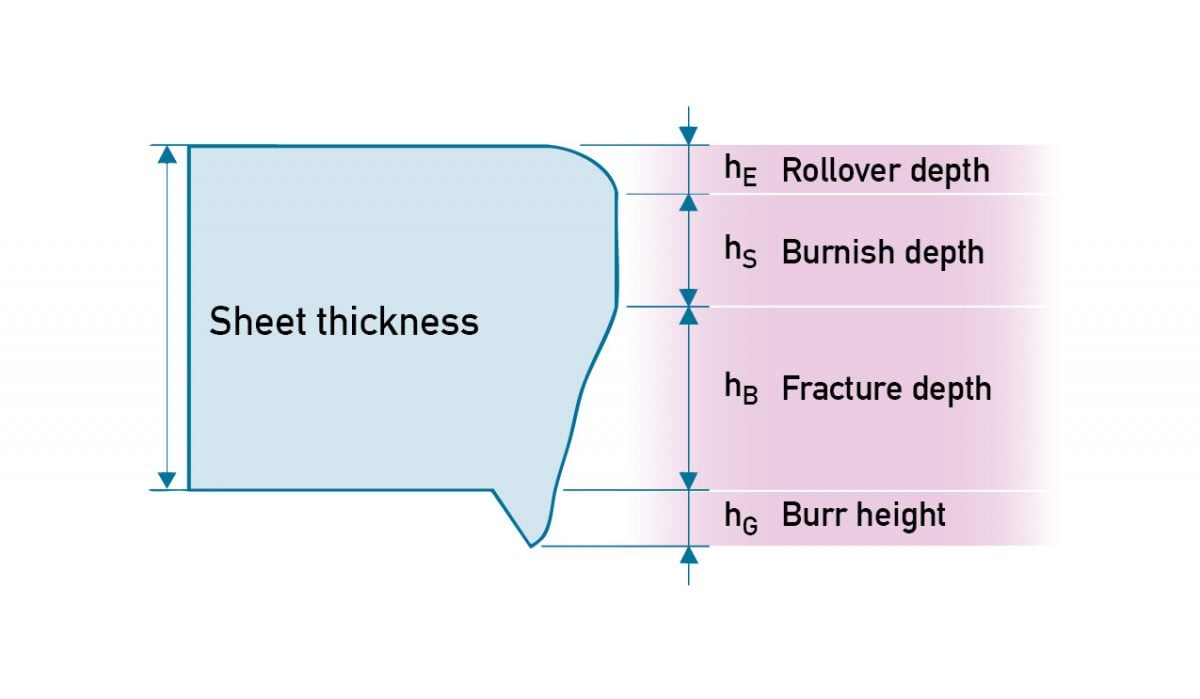

Even the most mundane byproducts of machining – chips, shavings, and tiny fragments of metal – deserve attention during the design phase. These bits, collectively referred to as Foreign Object Debris (FOD), can accumulate in pockets, corners, or along tool paths.

Left unchecked FOD may scratch critical surfaces, dull cutting tools, or even cause catastrophic tool breakage. Burrs, the small raised edges left after cutting or shearing, present a related challenge: they can interfere with assembly, create stress concentrations, or catch on moving components, producing downstream quality issues.

Together, chips and burrs are subtle but persistent hazards, both to people and equipment, that can ultimately compromise both part performance and production efficiency.

Thoughtful designers anticipate FOD from the outset. Adequate clearances, gentle draft angles, and unobstructed pathways for chip evacuation allow material to exit cleanly during cutting; reducing the risk of trapped debris and minimizing burr formation. Features such as sloped pockets, chamfers, or through-holes can make a significant difference, ensuring smooth, uninterrupted machining.

Steve Jobs once said that Apple lived at “the intersection of technology and the liberal arts.” For engineers and manufacturers, the intersection looks a little different: it’s where creative vision meets manufacturable reality.

That space is where Prismier thrives.

We also understand the pressures you face. Every project asks you to balance aesthetics, cost, performance, and speed-to-market, often all at once. Our job is to make sure your ideas navigate that balancing act intact – without being diluted, over-engineered, or priced out of reality.

We work alongside you, not as critics, but as partners, bringing practical experience and an eye for the subtle adjustments that can have an outsized impact.

Sometimes that means recommending a gentle radius instead of a perfectly sharp corner, or pointing out a tolerance that’s possibly tighter than it truly needs to be. Other times, it’s as simple as repositioning a feature so chips and debris evacuate cleanly, or slightly thickening a wall to prevent flex during machining. These changes are not compromises – they are small interventions that safeguard your vision while smoothing the path to production.

By thinking ahead in this way, you preserve both the design intent and the manufacturability of your part. You’re able to keep the lines elegant, the finishes precise, and the performance consistent, all while avoiding surprises on the shop floor. In essence, we help you translate your ideas into real, tangible parts that meet your expectations without adding cost, time, or unnecessary complexity.

The iPhone 4 antenna taught Apple, and the rest of us, that perfection in design isn’t enough. Success depends on manufacturability. You don’t have to be Steve Jobs on a beach in Hawaii, fielding crisis calls, to appreciate that lesson. You just have to care about making parts that work, last, and don’t drain your budget.

The truth is, manufacturability isn’t a buzzword or an afterthought – it’s the quiet discipline that turns digital models into real products that fit, function, and endure. A part that looks stunning on a screen means little if it wobbles on the production floor, costs twice as much to run, or fails under pressure.

Involving manufacturability early transforms those risks into opportunities: corners get refined, tolerances get right-sized, and hidden costs get caught before they become headaches.

That’s where having the right partner matters. At Prismier, we sit with you at that critical intersection where ideas meet machines. We bring practical expertise to the table, not to rein in your vision, but to protect it – making sure your boldest designs survive contact with reality, emerging beautiful, functional, and ready for the world.

Because in the end, great design isn’t just about how something looks, it’s about how well it’s made. And when you build with manufacturability in mind, you’re not just creating a product, you’re creating something that lasts, something that scales, and something you can be proud of.

For our part, Prismier takes pride in every service we provide, not just CNC machining. From sheet metal and metal stamping to 3D printing, injection molding, die casting, assembly, and logistics, we help you move from prototype to production without losing sight of your goals. And with ISO 9001:2015 certification and advanced process controls, we deliver speed without sacrificing quality.

So are you ready to get started? Contact Prismier for your next custom metal or plastic project. Let’s design smarter, manufacture better - and turn good ideas into great products, together.