Quality

The Swiss Army Knife of Manufacturing

June 22, 2020

Behind every breakthrough product is a quiet scramble to find the right manufacturer. Bringing together speed, precision, and scalability isn’t easy, but it’s what separates good projects from great outcomes.

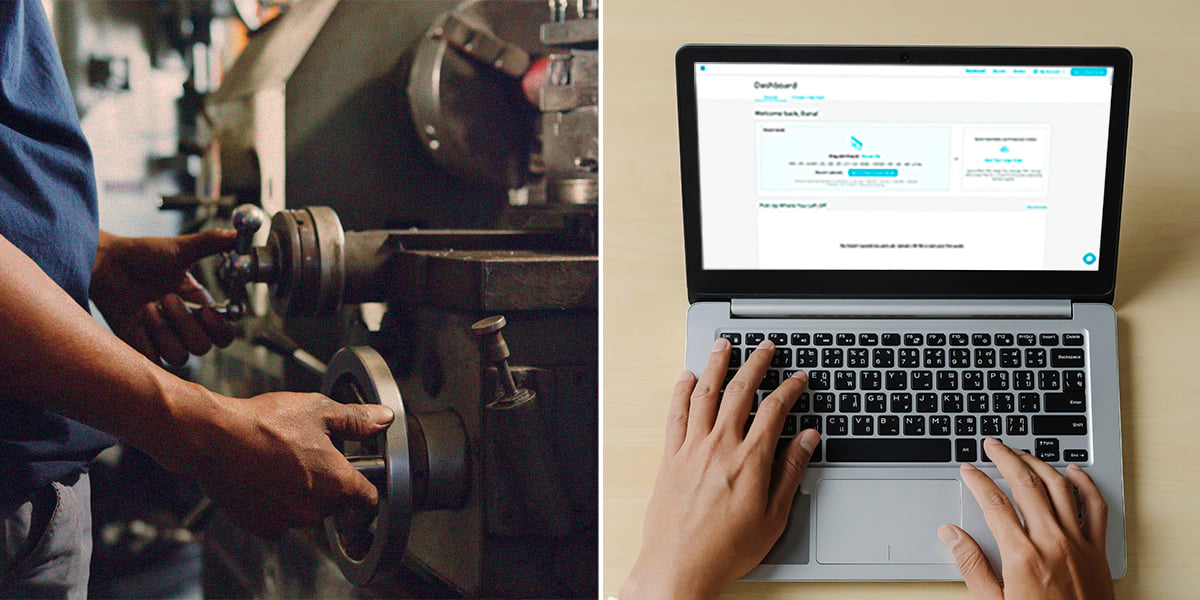

Manufacturing has also evolved significantly over the past two decades. On one end of the spectrum are traditional job shops, offering high craftsmanship and personal service. On the other end, digital marketplaces promise rapid turnaround and instant quoting.

What we’ve learned from our two decades is that each approach has obvious strengths… and tradeoffs.

Specifically, there are job shops who typically specialize in just one commodity and can supply prototype, production, or in rare cases, both. The average job shop may still be first generation or transitioning into the 2nd generation. Limited resources, technology, and family dynamics can hamper the ability to scale.

On the other hand there are focused marketplace companies that may obscure where and how a component is being made, offering their clients limited visibility into the production process. Because of the quick, anonymous nature of the transactions, these companies often don’t instill confidence; leaving customers uncertain about how their production parts are made.

At Prismier we offer a compelling hybrid manufacturing model that comes without the tradeoffs; combining the speed and responsiveness of modern platforms with the precision, accountability, and engineering depth of a true manufacturing partner.

To that end, we combine tech-forward methodologies with deep industry expertise to help our customers move seamlessly from prototype to production at scale.

Understanding industry nuances is also key, as OEM customers and their sourcing groups typically distinguish between prototype-focused and production-focused companies. Though design engineers often trust prototypers to bring their vision to life, sourcing groups generally prioritize cost-effectiveness when it comes to production.

At Prismier, we bring convenience, cost-effectiveness and capability without compromise, and when you partner with us, you get manufacturing that’s built to support real business progress.

Most industry professionals are familiar with the personalized service of a local job shop; where relationships, trust, and technical know-how drive quality work. These operations excel at specialized parts and hands-on support, often becoming long-term partners in niche applications.

However, their strengths can also limit scalability. Traditional shops may be constrained by local resources, legacy workflows, or a narrow set of capabilities. Traditional shops often have limitations like outdated technology, manual quoting, and minimal staff. While their skilled workers are great at their craft, they might not be as strong in communication or project management. This can lead to a fixed approach that, while sometimes good, can also limit options. Also, older equipment might make their prices seem attractive, but it means they can’t scale easily and rely on a lot of manual work, which can cause issues when you move to production. While they can be well-suited for early-stage collaboration or low-volume runs, they may struggle to keep pace with evolving design needs or accelerated timelines.

Digital platforms like Xometry, Fictiv, and Protolabs have introduced a new paradigm in custom part manufacturing. By aggregating supplier networks and automating pricing and procurement, they offer instant access to manufacturing capacity while providing transparent lead times.

This model works well for straightforward, one-off parts, or when time-to-quote is the top priority. However, these platforms often trade depth for speed. Buyers often have limited visibility into which shop is building their part, what processes are used, or how changes in design might impact cost or quality.

Their suppliers (the Job Shops), in turn, operate under price compression and limited communication in a marketplace environment, sometimes at the expense of long-term relationships or technical consultation.

It also turns out that automated marketplace algorithms aren’t perfect at estimating jobs. Shocking, right? Sometimes marketplace buyers don’t get the right price for their component, and would have benefited from having someone with experience examine their CAD file and quote the job using human intuition, experience, creativity and logic… instead of AI.

Put simply, marketplaces are optimized for transactions and small projects; not for collaboration that delivers sustained, scalable, reliable, cost-efficient production.

Prismier takes a different path: delivering engineering know-how with marketplace style efficiency.

As a hybrid manufacturer, we integrate the best elements of both worlds – human expertise and digital efficiency – to deliver what we call Manufacturing Simplified. We actually manufacture things and all project management, quality, finishing, assembly, and warehousing are under our roof. This approach empowers customers to move from concept to production without compromising on insight, quality, or scalability.

During the prototyping phase, Prismier works closely with your engineering team to evaluate not just form and function, but also manufacturability at scale. We flag design elements such as material choices, tolerances, and complex geometries that might be feasible in a prototype, but inefficient or cost-prohibitive in production.

By addressing these factors early, Prismier helps you minimize the risk of redesigns; ensuring a smooth transition to manufacturing. To that end, our experts apply a Design for Manufacturability (DFM) mindset from day one, guiding you toward smarter design decisions without compromising performance.

And when you’re ready for manufacture, Prismier is ready for you combining advanced technology with deep industry expertise to offer a unique hybrid manufacturing approach. This allows them to seamlessly guide projects from prototype to full-scale production, ensuring both speed and precision. With extensive capabilities across various materials and methods, Prismier simplifies the manufacturing process, making it scalable and reliable for diverse customer needs.

The result is a prototype that’s not only functional, but is fully aligned with your production goals. Prismier doesn’t just help you prove a concept, we help you build a foundation for scaling your business. From day one, we engineer with real-world manufacturing in mind.

Our philosophy is simple: we take full responsibility for delivering your manufactured solution and we really see ourselves as your true partner in getting your component done right. We take full responsibility for delivering your solution because, as our co-owner Mike puts it, “We put our name on the box!” This means we stand behind the work completely, making sure everything is vetted, quality-checked, and meets your needs, not just on paper, but for its actual purpose. This gives you peace of mind that both your design intent and product quality will be preserved; no matter how complex the project becomes, nor how many steps are involved.

You won’t have to coordinate between multiple vendors, chase down updates, or worry about miscommunication derailing your timeline. With Prismier, you gain a single, accountable partner who manages the details so you can stay focused on what drives your business.

Our customers gain a level of trust and convenience that turns manufacturing from a logistical burden into a seamless part of the supply chain.

Unlike algorithm-driven quoting systems, Prismier connects you with real people, such as experienced engineers, technologists and project managers who engage directly with your team from day one.

When you work with us you’re not submitting files into a black box; you’re having conversations with technologists who ask the right questions about tolerances, materials, volumes, and downstream processes.

With Prismier, you get a collaborative, human-first approach that feels more like working with a trusted shop than a faceless platform.

This personal engagement helps uncover risks early, refine your design intelligently, and ensure your part is not only manufacturable, but also optimized for scale, cost, and performance. The result isn’t just a better part; it’s a better process – every step of the way.

Prismier also brings this deep experience across multiple industries such as robotics, aerospace, medical, and industrial, and we put that knowledge and experience to work on every project.

From material selection to tolerance adjustments, we guide you toward solutions that streamline production, improve quality, and reduce costs. Our process delivers practical insights that are grounded in real-world know-how from people who care about getting it right.

At Prismier, we don’t just build parts, we help build businesses. Our mission goes beyond one-off jobs or quick-turn prototypes; we’re here to support the full arc of your product’s journey, from first concept to full-scale production.

We love working with teams that are pushing boundaries, launching new ideas, and scaling fast… and we take pride in being the kind of partner that grows with you.

Whether you’re an emerging startup or an established company bringing a new product to market, we think like entrepreneurs, not just manufacturers. By aligning our expertise with your long-term vision, we help lay the groundwork for growth that’s not only achievable, but sustainable.

And when your business thrives, we know we’ve done our job right, and that’s what drives us!

Complex products don’t come to life with a one-size-fits-all approach, and neither do our solutions. Prismier combines a wide range of manufacturing capabilities to meet the specific demands of your part, no matter the material, method, or volume.

From rapid prototyping to full-scale production, we bring together the right technologies at the right time to move your project forward. Whether it’s a single precision component or a multi-step assembly, we streamline the path from concept to completion with speed, consistency, and attention to detail.

Our comprehensive offering includes:

With this broad range of capabilities at our fingertips, we’re able to guide each project down the most efficient and effective path; whether that means a straightforward, single-process part or a more complex, multi-step build with unique requirements.

Prismier is ISO 9001:2015 certified by NSF-ISR, reflecting our ongoing investment in quality systems, traceability, and performance standards. We also uphold strict ITAR standards, ensuring the highest level of trust and security for sensitive projects. Depending on your industry and specific needs, we can meet various quality specifications, including First Article Inspection (FAI), different levels of PPAP, and AS9102. This comprehensive approach means every part we deliver meets the highest criteria for precision and reliability. For customers, that means peace of mind: every part we deliver meets rigorous criteria for precision and reliability.

While digital platforms are useful for quickly connecting customers to manufacturers, they often fall short when a project demands continuity, deep engineering insight, or a long-term production strategy.

On the other end of the spectrum, traditional job shops offer that personal touch and craftsmanship, but may lack the speed, scale, or technical infrastructure required for today’s evolving needs.

Prismier bridges that divide – bringing together the efficiency of modern systems with the reliability, responsiveness, and expertise of a true manufacturing partner. And with our hybrid approach, our digital tools are crucial for enhancing efficiency, communication, and scalability. This suite includes our ERP system for production, CRM for customer and project management, and digital dashboards for real-time monitoring. Integrating these technologies allows for seamless collaboration, faster turnaround times, and improved decision-making, setting us apart from traditional job shops and transactional marketplaces.

If you’re looking for more than just a fast quote and you want a team that stands with you from prototype through production – Prismier offers a smarter, more scalable path forward.

We simplify the manufacturing process without sacrificing precision or intent, ensuring your parts are built right, every time. It’s how we help our customers move faster, build stronger, and scale with confidence.

Whether you’re at the initial concept stage, prototype stage, pre-launch or full scale production, Prismier can deliver every step of the way. Are you ready to get rolling with your next great project? Get started early, get started today with Prismier.