Quality

The Swiss Army Knife of Manufacturing

June 22, 2020

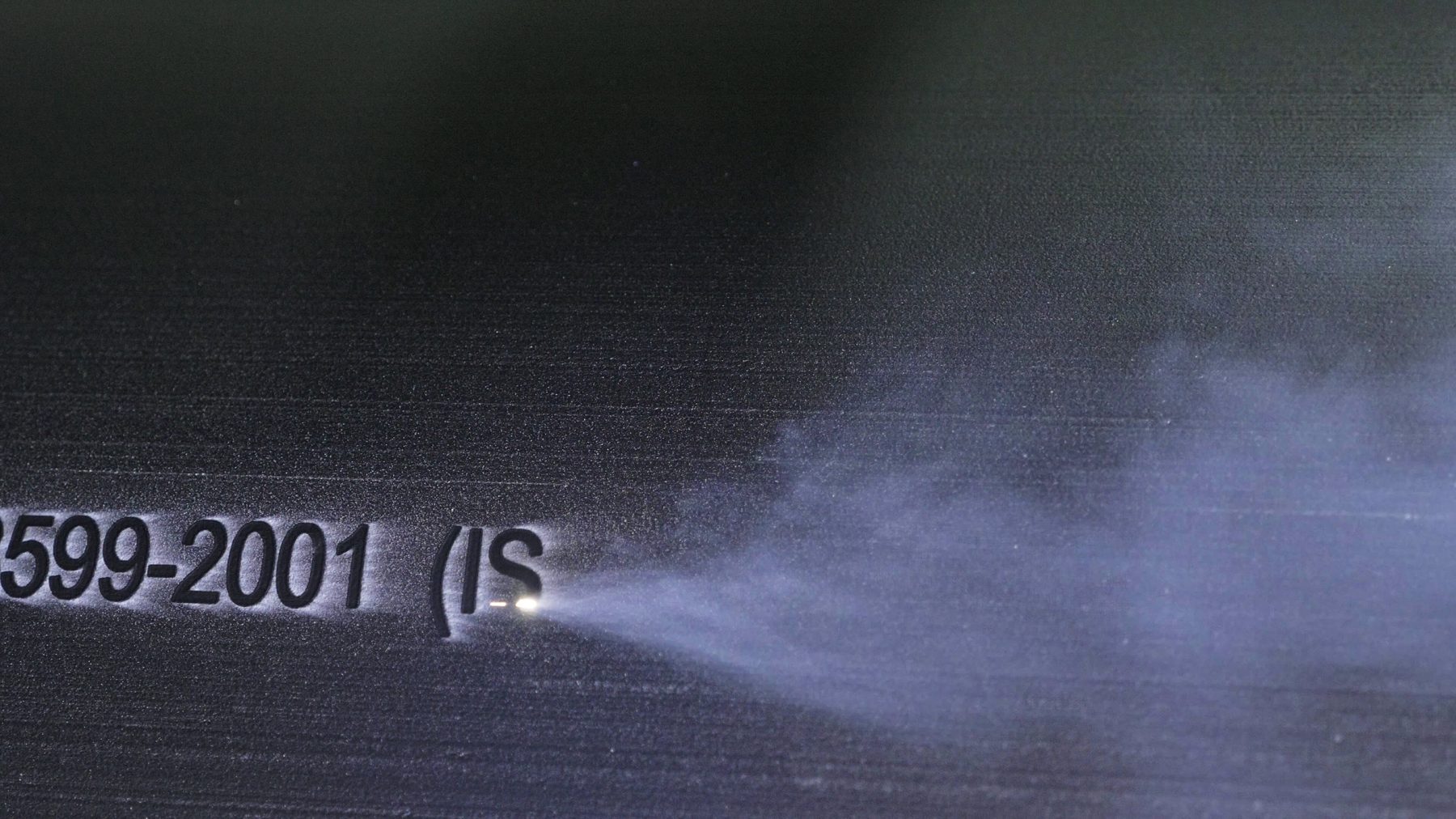

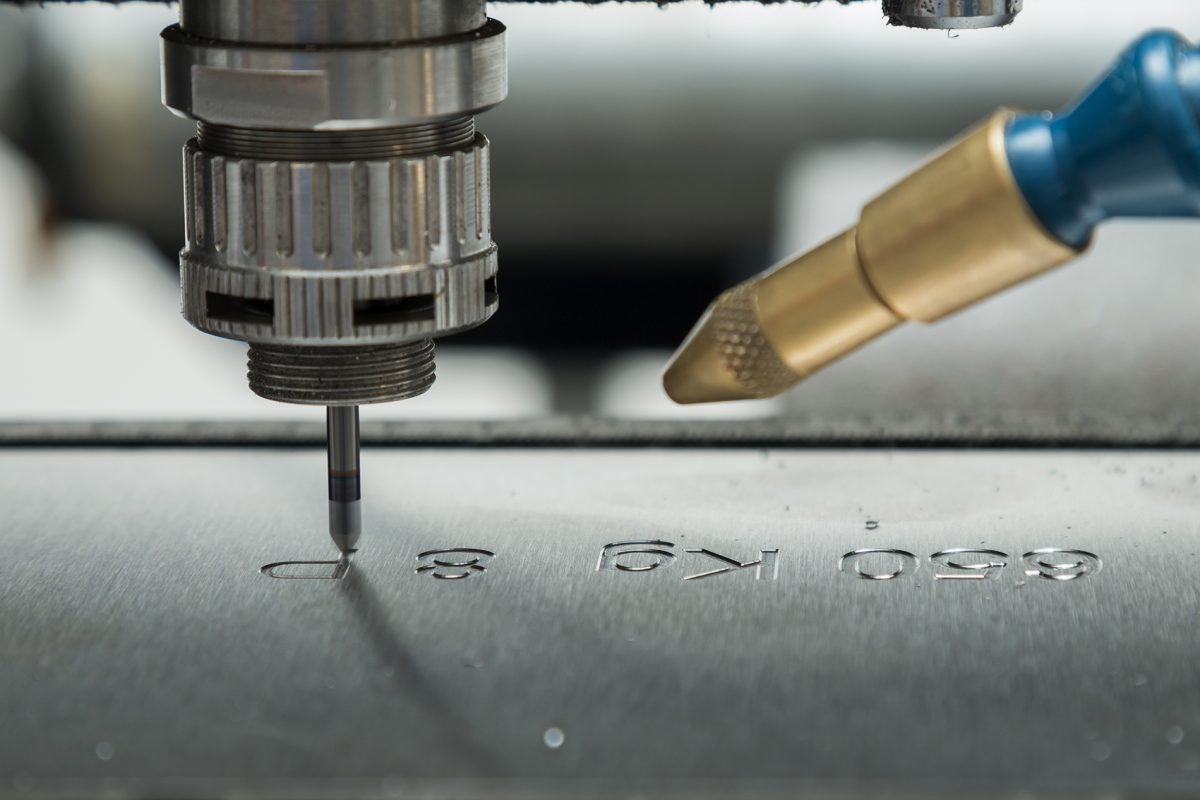

Part marking is every bit as important in manufacturing as surface finishing and adherence to tolerances (well, almost). Custom parts can all too easily be mistaken for one another. Without permanent marking or at least proper labeling, parts might end up in the wrong assembly or be shipped to the wrong customer, potentially leading to disastrous results. Furthermore, important legal or regulatory information could be required, or helpful instructions could simply be desired. That’s why it’s common practice to apply part numbers and descriptions, serial numbers, barcodes, and company logos or other artwork to individual metal and plastic parts, assemblies, and final inner and/or outer packaging. Part marking is to manufactured parts what labels are to soup cans and road markers are to interstate highways. Without proper part marking, we’d be lost.

Fortunately, there’s no shortage of ways to identify these machined, plastic injection molded, diecast, 3D printed, stamped or laser-cut metal components and assemblies. Such methods include so-called bag and tag, rubber stamp or silk-screen, coining, and our favorite, laser marking. Let’s go over a few of the various ways to mark parts along with some of the why, where, and when of each. And be sure you stick with us to the end. You won’t regret it!

We’ve covered many of the various methods of part marking here, from the more primitive to the most advanced. Depending on the specific application and industry, any of these methods could be acceptable. We’ve found that in most applications, the method itself is not critical, as long as the parts are legibly marked according to the customer requirements for permanence. Need to mark some parts? Give Prismier a call. Happy marking.

If you'd like to know more, pick up the phone and call us at (630) 592-4515 or email us at sales@prismier.com. Or if you're ready for a quote, email quotes@prismier.com. We'll be happy to discuss your options.